1, pressure riveting machine pressure riveting process processing content: pressure riveting nuts, screws, studs and custom hardware pressure riveting parts (guide pin, positioning support column, etc.), electrostatic hand bowl, pressure riveting wrench, etc.;

2. For the riveting parts close to the edge of the product or the periphery of the hole, the edge of the product or the periphery of the hole will be obviously deformed after the riveting, according to the deformation of the material to take corresponding measures (such as shape correction/or grinding) to meet the requirements of the size and appearance of the drawings.

3. After riveting, there shall be no distortion or deviation. It is necessary to ensure that the thread is concentric with its corresponding hole.

4, pressure riveting parts of the material, specifications and models must be consistent with the drawings, not wrong specifications;

5, after the pressure riveting pressure riveting parts around shall not be raised or depression obvious deformation, shall not have obvious surface treatment can not cover the imprint or mold.

6, after the pressure riveting shall not tilt the pressure riveting parts shall not loose, fall off, must test its firmness; The value of push, pull and torsion must meet the requirements specified in PEM of the riveting parts.

7. Before pressing riveting, we must timely confirm whether the external identification of pressing riveting parts used by the production line and the physical object (material, specification and model) in the packaging bag meet the requirements of the drawings, and whether there is a mixing phenomenon in the packaging bag.

8, for in the bending edge or die forming edge of the close pressure riveting parts to pay attention to, especially thread, appearance (deformation) to focus on detection.

9, after the pressure riveting products on the pressure riveting parts of the material, specifications and threads for random sampling inspection, whether to meet the requirements of the drawings, there is no leakage, wrong pressure, wrong position, pressure mixing phenomenon.

10. After riveting, the thread of the riveting parts must be qualified.

11. After the riveting is completed, it is necessary to check whether the flatness is within the range. If it exceeds the standard, it is necessary to turn into fitter alignment treatment.

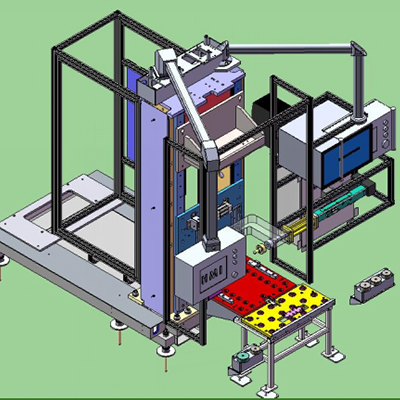

12, a single product pressure riveting studs, screws number is more, some products will make special fixture for pressure riveting, the other need to do a special gauge to check whether there is leakage or wrong pressure and other defects; Shanghai Tubo Industrial Technology Co., Ltd. focuses on riveting technology and riveting assembly solutions.